E10 error code

An E10 error on your processor's display indicates the dryer fan motor is running too slow or not running at all.

Typically, when your processor experiences an E10 error it's a good idea to replace the electronics kit within your processor because either the fan motor/sensor is bad or the Control Board is not talking to the fan properly. In either case, a new electronics kit comes with a new fan motor and Control Board as well as the AC Power Board. Replacing your old parts will eliminate the E10 error.

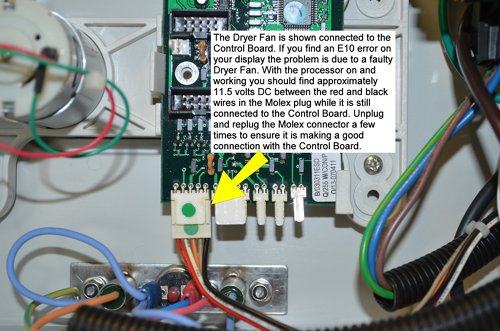

You can remove the dryer fan motor's Molex connector from the Control Board and inspect the pins within the Molex connector to ensure they are held securely in place and not broken. The Molex connector plugs into the Control Board on the bottom most left side of the Control Board. Refer to the photo below for clarification.

To get to the dryer fan motor and the Control Board, power the processor off and then remove the phillips screw located just above the AC plug in the back of the processor. Lift the blue lid and carefully lay it on the white lid, out of the way. There are wires attached to the bottom of the blue lid so don't pull it up too fast when removing the lid. To make it easier for you, remove the side panel next. If you don't know how to remove the side panel I suggest you watch the short video on our website that shows how to remove a side panel.

Click HERE to watch the video.

With the side panel removed locate the dryer fan's Molex connector which is connected to the Control Board. Remove the Molex connector and inspect the pins within the connector for possible problems.

The information below tells you how your dryer fan motor will operate when normal and when any of the wires in the dryer fan's Molex connector are bad.

NORMAL OPERATION of the dryer fan motor is … upon first turning the machine on the fan will operate at high speed during the complete initiation cycle. In the cool-down cycle the fan returns to normal speed until the machine enters its stand-by cycle. In stand-by the fan will still run, but very slowly. When film is being processed the fan will operate at normal speed until the processing cycle is complete.

If the WHITE FAN WIRE is defective ... the fan WILL ALWAYS operate at high speed through the initiation, cool-down, stand-by and processing cycles. It WILL NOT turn off unless you power the machine down. The heating element works normally through all cycles. It’s on when it should be on and it’s off when it should be off.

If the GRAY FAN WIRE is defective ... the fan will operate at high speed through the complete initiation cycle. The fan will operate normally during the cool-down cycle. After the cool-down cycle completes the machine will go into an E10 error. At this time the fan will turn off.

If the ORANGE or RED or BLACK FAN WIRES are defective ... the fan WILL NOT operate at all. The heating element WILL NOT work at all. The initiation cycle will count all the way down to zero and the cool-down cycle will also start and finish. The machine will then go into an E10 error rather than go into its stand-by cycle.

If you get any of the above indications, you might want to inspect the wire and connection associated with the problem you are having. If you find a bad wire connection, you may be able to eliminate the E10 error.

An E10 error on your processor's display indicates the dryer fan motor is running too slow or not running at all.

Typically, when your processor experiences an E10 error it's a good idea to replace the electronics kit within your processor because either the fan motor/sensor is bad or the Control Board is not talking to the fan properly. In either case, a new electronics kit comes with a new fan motor and Control Board as well as the AC Power Board. Replacing your old parts will eliminate the E10 error.

You can remove the dryer fan motor's Molex connector from the Control Board and inspect the pins within the Molex connector to ensure they are held securely in place and not broken. The Molex connector plugs into the Control Board on the bottom most left side of the Control Board. Refer to the photo below for clarification.

To get to the dryer fan motor and the Control Board, power the processor off and then remove the phillips screw located just above the AC plug in the back of the processor. Lift the blue lid and carefully lay it on the white lid, out of the way. There are wires attached to the bottom of the blue lid so don't pull it up too fast when removing the lid. To make it easier for you, remove the side panel next. If you don't know how to remove the side panel I suggest you watch the short video on our website that shows how to remove a side panel.

Click HERE to watch the video.

With the side panel removed locate the dryer fan's Molex connector which is connected to the Control Board. Remove the Molex connector and inspect the pins within the connector for possible problems.

The information below tells you how your dryer fan motor will operate when normal and when any of the wires in the dryer fan's Molex connector are bad.

NORMAL OPERATION of the dryer fan motor is … upon first turning the machine on the fan will operate at high speed during the complete initiation cycle. In the cool-down cycle the fan returns to normal speed until the machine enters its stand-by cycle. In stand-by the fan will still run, but very slowly. When film is being processed the fan will operate at normal speed until the processing cycle is complete.

If the WHITE FAN WIRE is defective ... the fan WILL ALWAYS operate at high speed through the initiation, cool-down, stand-by and processing cycles. It WILL NOT turn off unless you power the machine down. The heating element works normally through all cycles. It’s on when it should be on and it’s off when it should be off.

If the GRAY FAN WIRE is defective ... the fan will operate at high speed through the complete initiation cycle. The fan will operate normally during the cool-down cycle. After the cool-down cycle completes the machine will go into an E10 error. At this time the fan will turn off.

If the ORANGE or RED or BLACK FAN WIRES are defective ... the fan WILL NOT operate at all. The heating element WILL NOT work at all. The initiation cycle will count all the way down to zero and the cool-down cycle will also start and finish. The machine will then go into an E10 error rather than go into its stand-by cycle.

If you get any of the above indications, you might want to inspect the wire and connection associated with the problem you are having. If you find a bad wire connection, you may be able to eliminate the E10 error.